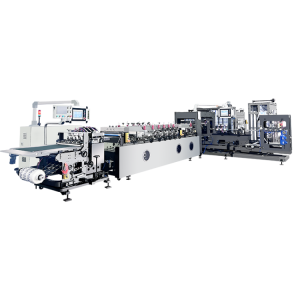

NCA300SJA awtomatikong paggawa ng bag at spout-welding machine

Paggamit

1. Ang makina ay ginagamit para sa paggawa ng three-side sealing bag o stand-up bag na may spout mula sa plastic laminated film.

2. Ang makina ay nagsisimula mula sa hindi pag -ibig, sa turn ay magnetic powder preno, dancer arm roller tension pag -aayos, pagputol, pagwawasto, dobleng layer na nag -coinciding, ilalim ng film feed at inserting, (hugis puncher), servo drive, spout feed, spout hot sealing, spout cold sealing, cross hot sealing, cross cold sealing, (hugis puncher), pagsubaybay ng color code, servo traction, pagputol (hugis ng suntok,, mga produkto na nag -aaksaya ng table.

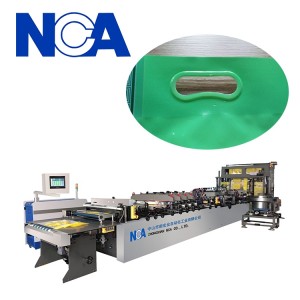

Kalamangan

1.Welding nozzle, paggawa ng bag

2. Double Independent Bag, Imbakan (Refueling nang Walang Stop)

3.Double Cutting Knife, Double Roll

Proseso ng Paggawa

Ang makina ay nagsisimula mula sa hindi pag -ibig, sa turn ay magnetic powder preno, dancer arm roller tension pag -aayos, pagputol, pagwawasto, dobleng layer na nag -tutugma, ilalim ng film inserting, hugis puncher, servo drive, spout feed, spout hot sealing, spout cold sealing, cross hot sealing, cross cold sealing, pagsubaybay sa code ng kulay, servo traction, pagputol (hugis puncher), mga produkto na nag -aalis ng talahanayan.

Mga parameter ng diskarte sa makina

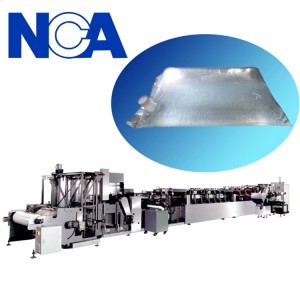

| 1 | Materyal ng pelikula | Plastik na nakalamina na pelikula |

| 2 | Kapasidad: | Single bag feed : MAX35-40PCS/Mindouble Bag Feed : MAX 70-80PCS/MIN |

| 3 | Kapal ng materyal | 0.06 ~ 0.15mm |

| 4 | Uri ng spout | Iba't ibang uri ng maliit na plastik na spout. |

| 5 | (Bilis para sa spout pouch, tiyak na bilis ayon sa laki ng supot at materyal) | |

| 6 | Laki ng Pouch: (L × W) | Single bag feed : MAX300 × 200mmDouble bag feed : MAX150 × 100mm |

| 7 | Kabuuang lakas | Mga 25kw |

| 8 | Power boltahe | AC380V, 50Hz, 3p |

| 9 | Air Pressure: | 0.5-0.7Mpa |

| 10 | Paglamig ng tubig: | 10L/min |

| 11 | Taas ng Talahanayan ng Paggawa ng Machine: | 950mm |

| Pangasiwaan ang Operation Taas 850mm | ||

| 12 | Dimensyon ng makina (max): | L × W × H: 8200mm × 3500mm × 2000mm |

| 13 | Timbang ng makina: | mga 5000kg |

| 14 | Kulay ng makina: | Grey (wallboard)/ hindi kinakalawang na asero (bantay board) |